This has been an interesting learning curve. While some think using thermatics to cool a 2 stroke diesel is problematic, we are doing that, and saving fuel and power to drive the original huge fan. If you are thinking of going down this road there is a rule you MUST follow, find out the stats on how much air your factory fitted fan is moving, and use enough thermatics to get pretty close to that. In our case it was 7,000 litres of air a second or 14,000 cfm if memory serves me correctly. That is the amount of air moved by the original fan at full song. If you were to fit thermatics that moved say 7,000 cfm you will only be driving in winter, at night, before your motor overheats and dies. But if you do the homework and come somewhere close to the original it can be done. DO NOT attempt this without finding out that magic figure, I promise you tears are lying in wait for you !

We also had another reason for doing this, with 3000 watts of solar we had a huge surplus of energy to drive thermatics, and I want to wring every last drop we can from our small spec 6V92T Detroit. Even when you find the magic figure above, all is not guaranteed, another proviso I would make is that you must know your radiator is clean and the ONLY way to do this is to have it reconditioned, no good to say I did that 3 years ago, it must be performing properly for you to know if this works or not.The energy required to drive the original fan is in excess of 10% of that generated by the motor. So we wanted to claw that back.

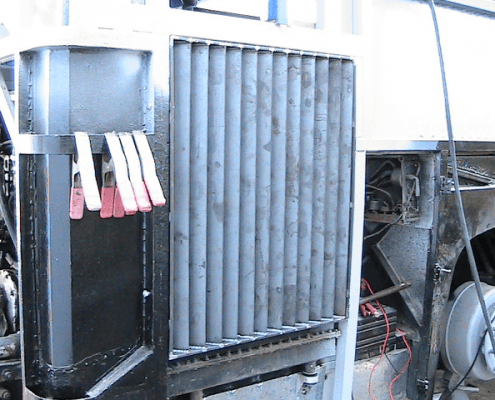

So the first step was to purchase 4 x 14″ hi performance fans from Davies Craig (with the 16″ fan motors in them). They were good for 6000 cfm, we could not fit anymore on the original radiator so added another, a Ford AU radiator and fans purchased as a package from e bay to see if this would be sufficient to keep VP cool on a hot day. This took the total to about 8,000 or thereabouts cfm. This was sufficient for night travel but on a hot day, towing 4 tonnes of trailer we were restricted to 80 kph or the temperature gauge would start to creep up.

So we pulled the AU radiator and had PWR make a custom aluminium radiator, as big as we could fit in the spot, which in truth was about the same size as the AU radiator but 3 times the thickness. We purchased 2 x 16″ Davies Craig fans, made a very tight shroud and bolted it all up. Almost there but not quite, if we pushed over 100 kph VP stated to run a little hot, not dramatically but not perfect. So I put the AU radiator on the trailer and set it up to come on if we ever got to 90 deg C. Over winter we didn’t even bother with any coolant in it, we never got over 80 deg C.

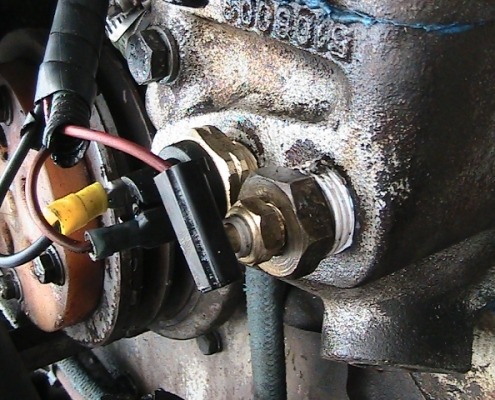

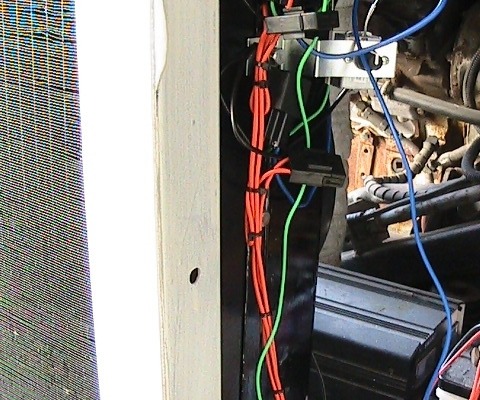

However we have recently done a trip to Central Queensland and we had some issues with fans not running, but if they were switched to solar they would, fans coming on or off etc. It took several bouts of investigating to find that the blade fuse holder the fans ran through was not capable of handling 3 high current lines, when they were all beside each other, there was heat being generated, resistance, loose fuses etc etc. It has taken over 2 years for this issue to slowly develop. As each thermostatic control had it’s own fuse anyway, I put those directly to the big cable supplying the fuse box and headed off again. Wow, along the Bruce on a hot afternoon sitting on 105 plus kph and the gauge sat dead steady on 80 deg C, exactly where we wanted it. So, the lesson from all of this is that it can be done, but it is far more involved that just throwing the old fan out and strapping a couple of ebay cheapies onto your radiator and expecting cooling system performance. That way lies disaster. As the AU radiator is already on the trailer I will leave it there, it may come into play on a 40 deg day, halfway up Toowoomba range when you are screaming your head off in second gear, but I doubt it.